Recent Posts

Get in touch!

Fusce varius, dolor tempor interdum tristiquei bibendum service life.

- +90 [312] 394 07 58

- İvedik OSB, 1444. Cd. No: 1 Ostim, Ankara

- info@yildizpolietilen.com

- E-Katalog

Accredited Experiments

Akredite

Deneylerimiz

Yıldız Polietilen olarak, ürettiğimiz polietilen ürünlerin en yüksek kalite standartlarına uygun olmasını ve müşteri memnuniyetini sağlamayı hedefliyoruz.

YOĞUNLUK TAYİNİ (TS EN ISO 1183-1)

Yoğunluk, bir malzemenin belirli bir sıcaklıkta kütlesinin hacmine oranıdır. g/cm³, kg/cm³, g/ml, kg/l gibi değişik birimlerle ifade edilebilir. Yoğunluk, genelde malzemelerin fiziksel yapısındaki veya bileşimindeki değişimleri takip etmek için kullanılır. TS EN ISO 1183-1 standardında yoğunluk tespitinde üç farklı yöntem tanımlanmaktadır. Metod A : Daldırma Yöntemi, Metod B : Piknometre Yöntemi, Metod C: Titrasyon Yöntemi. Laboratuvarımızda, Metod A Yöntemi kullanılmaktadır. Sonuçlar, g/cm³ cinsinden verilmektedir.

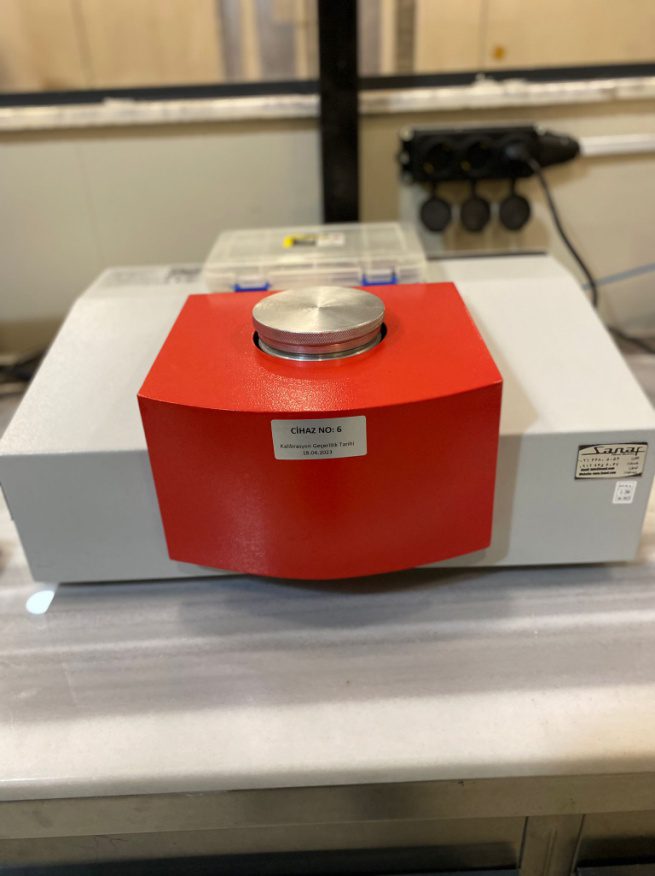

ERİME AKIŞ HIZI (MFR) TAYİNİ (TS EN ISO 1133-1)

MFR değeri 10 dakikalık süre içerisinde belirli sıcaklık, yük altında, belirli uzunluk ve çaptaki kalıptan akan erimiş malzemenin gram olarak miktarıdır. MFR değeri malzemenin işlenme ve kaynak parametrelerinin belirlenmesi için önemlidir. TS EN ISO 1133-1 Standardında erime akış hızı için iki farklı yöntem tanımlanmaktadır. Metod A: Kütlesel Akış Hızı

( MFR ) ve Metod B: Hacimsel Akış Hızı ( MVR ). Laboratuvarımızda, Metod A Yöntemi kullanılmaktadır. Sonuçlar, g/10 dk cinsinden verilmektedir.

OKSİDASYON İNDÜKSİYON SÜRESİ (OIT) (TS EN ISO 11357-6)

PE ve PP gibi plastik malzemeler oksijen ve yüksek ısıya maruz kaldıklarında mekanik özelliklerini kaybederler. Plastik malzemeleri oksidasyon olarak bilinen bu durumdan korumak termal kararlalılığını sağlamak için imalat sırasında antioksidan içeren hammadde kullanılması gereklidir. Plastik malzemelerin termal kararlılığı “Oksidasyon İndüksiyon Süresi (OIT)” olarak bilinir. Malzemenin termal açıdan ne kadar kararlı olduğunun ölçüsüdür. Dakika cinsinden ifade edilir. TS EN ISO 12201-1 standardında malzemenin 200 °C de 20 dakikadan önce bozulması istenmemektedir. 20 dakikadan daha kısa OIT değerine sahip malzemeler işlenme veya kaynak sırasında yüksek sıcaklıklarda bozulmaya başlar. Sonuç olarak ürünün kullanım ömrü kısalır.

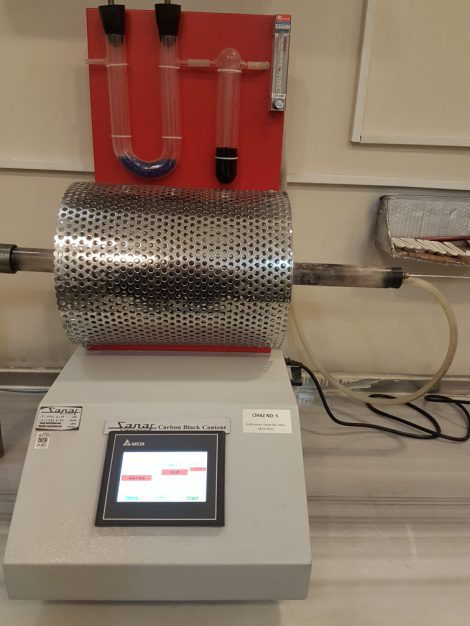

KARBON SİYAHI MİKTAR TAYİNİ (TS ISO 6964)

Ultraviyole ışığa maruz kalma birçok plastik türünün fiziksel ve kimyasal bozulmasını hızlandırır. Emilen UV ışığı, polimer malzemenin zayıf kimyasal bağlarını veya moleküler zincirlerini kırar. Bu durum daha kısa zincirlere yol açar ve bu da plastik malzemenin daha kırılgan hale gelmesine mekaniksel özelliklerinin düşmesine neden olur. Bunun önüne geçmek için imalat sırasında, içerisinde % 2- 2,5 karbon siyahı bulunan hammadde kullanılmalıdır. Ürün içerisinde bulunan karbon siyahı güneşten gelen UV ışınlarını tutarak plastiğin yapısının bozulmasını engellemektedir. Karbon Siyahı miktarı siyah boru ve ekleme parçalarının kullanım ömrü için önemli bir parametredir.

PİGMENT VEYA KARBON SİYAHI DAĞILIMININ DERECELENDİRİLMESİ (TS ISO 18553)

Karbon siyahının miktarı kadar dağılımı da önemlidir. Homojen dağılım göstermeyen karbon siyahı UV korumada istenilen performansı göstermeyecektir. Ayrıca homojen dağılımı olmayan hem karbon siyahı hem de renklendirme amaçlı kullanılan diğer renk pigmentleri ürünün mekaniksel özelliklerinde de azalmaya sebebiyet verecektir. Bu deneyde, 100 kat büyütme özelliğine sahip mikroskop altında numune içerisinde dağılım göstermiş karbon siyahı veya pigment parçacık boyutlarının ölçümü yapılmakta standarda göre dağılım derecesi belirlenmektedir. Standartta dağılım derecesinin ≤3 olması istenmektedir.

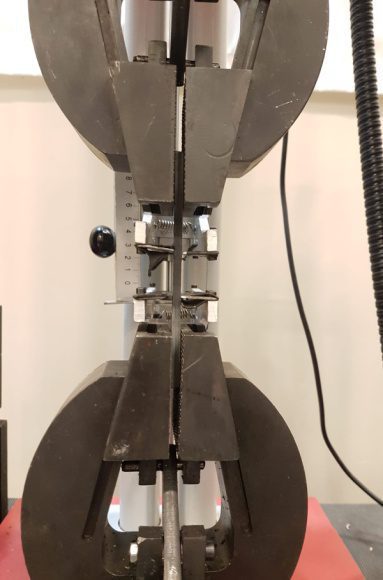

ÇEKME ÖZELLİKLERİNİN TAYİNİ (TS EN ISO 6259-1/3)

Deney numunesinin kalınlığına göre değişkenlik gösteren sabit bir hızla tek eksende kopana kadar çekilmesi sonrasında kopma anındaki uzunluk değişiminin ilk ölçülen uzunluğa oranı % uzama miktarını verir. Bu deney sonucunda, çekme mukavemeti ve akma mukavemeti de belirlenmektedir. Uzunluk değişimini belirlemede ekstansometre adı verilen ölçme aleti kullanılmaktadır. Çekme cihazları için özel geliştirilen programlar vasıtasıyla deney numunesinin çekilmesi sırasında gerilme, akma ve uzama gibi mekanik özelliklerine ait bilgiler elde edilmektedir.

UÇUCU MADDE MUHTEVASININ TAYİNİ (TS EN 12099)

Deney kapsamında polietilen (PE) boru malzemeleri test edilir. Bu deney metodu ayrıca, kalıplama ve ekstrüzyon malzemeleri ile polietilen boru sistemlerinde kullanılan elemanlara da uygulanabilir. Amaç, 105 °C lik etüvde tutulan deney malzemesinin içerisinde bulunun uçucu maddelerin sıcaklık etkisiyle uzaklaştırıldıktan sonraki kütle kaybını tespit etmektir. Kayıp uçucu madde muhtevasını verir. TS EN ISO 12201 – 1 Standardına göre uçucu madde muhtevasının en fazla mg/kg cinsinden ≤ 350 olması istenmektir.

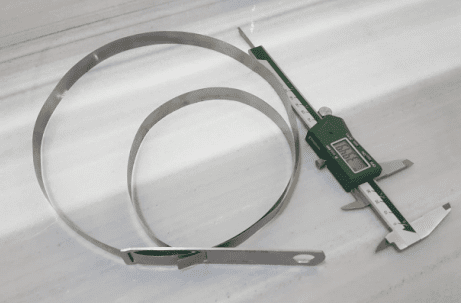

BOYUTLARIN TAYİNİ (TS EN ISO 3126)

Bu yöntemde, plastik boruların ve ekleme parçalarının geometrik özelliklerinin ölçülmesi ve değerlendirilmesi amaçlanmaktadır. Değerlendirme işlemi ilgili standart veya şartnamelere göre yapılmaktadır.

UZUNLUĞUNDAKİ DEĞİŞİM TAYİNİ (TS EN ISO 2505)

Termoplastik boruların sıcaklık değişimlerine maruz kaldıklarında boyca eski halini alabilme özelliğini belirlemek için yapılan bir deney yöntemidir. Et kalınlığı 16 mm ve altındaki borulara uygulanır.

İÇ BASINCA MUKAVEMETİN TAYİNİ (TS EN ISO 1167-1/2)

İç basınca mukavemet deneyi boru ve ek parçaların öngörülen kullanım süresini sağlayabilme yeteneğinin göstergesidir. Borularda, ekleme parçalarında, yada bunların karışımından oluşan ürün ağaçlarında standartta yada şartnamelerde istenen süre ve sıcaklıkta basınç sınıfına uygun bir iç basınca maruz bırakıldığında deney süresi boyunca patlama yada delinme olmaması gerekmektedir.