Recent Posts

Get in touch!

Fusce varius, dolor tempor interdum tristiquei bibendum service life.

- +90 [312] 394 07 58

- İvedik OSB, 1444. Cd. No: 1 Ostim, Ankara

- info@yildizpolietilen.com

- E-Katalog

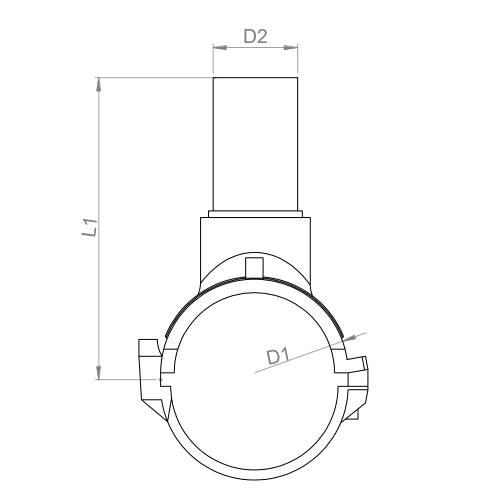

EF Tapping Valve

The integrated heater elements on the saddle, when connected to the welding unit, melt the HDPE material and create a homogeneous, strong, and leak-proof joint. EF Tapping Valves can be manufactured in various diameters and angles according to project requirements, offering flexible solutions for different pipeline systems.

EF Tapping Valve – Easy and Reliable in HDPE Pipe Systems

Product Description

The integrated heater elements on the saddle, when connected to the welding unit, melt the HDPE material and create a homogeneous, strong, and leak-proof joint. EF Tapping Valves can be manufactured in various diameters and angles according to project requirements, offering flexible solutions for different pipeline systems.

Areas of Use

-

Potable water distribution and transmission lines

-

Natural gas and LPG pipe systems

-

Industrial liquid and gas transportation lines

-

Sewerage and stormwater networks

-

Agricultural irrigation systems

-

New line connections or branching from existing pipelines

Advantages

-

Fast, secure, and durable connection with electrofusion technology

-

Provides excellent sealing between mainline and branch connections

-

High resistance to pressure and chemical impacts

-

Long service life against corrosion and external factors

-

Custom manufacturing in special diameters and angles as per project needs

-

Reduces labor costs with easy installation

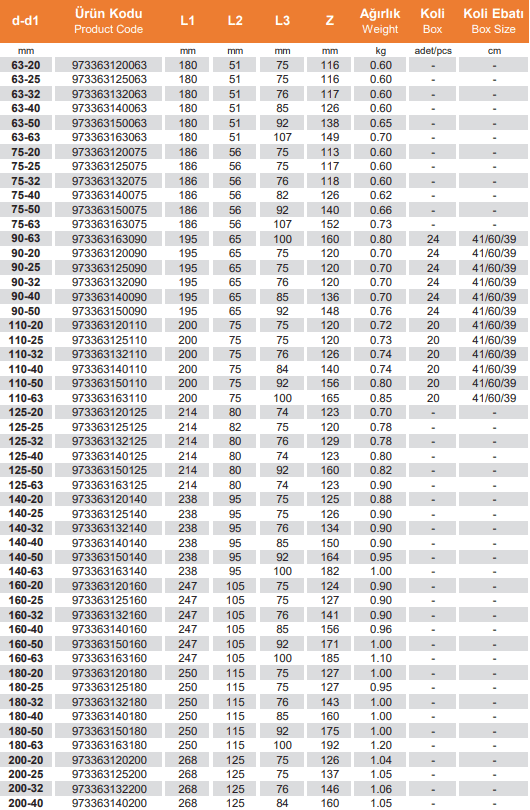

Technical Specifications

-

Material: HDPE (PE100)

-

Connection Method: Electrofusion Welding

-

Diameter Range: Ø20 mm – Ø1200 mm (special sizes available on request)

-

Pressure Class: PN10 / PN16

-

Standards & Conformity: ISO 4427, EN 12201, EN 1555