Recent Posts

Get in touch!

Fusce varius, dolor tempor interdum tristiquei bibendum service life.

- +90 [312] 394 07 58

- İvedik OSB, 1444. Cd. No: 1 Ostim, Ankara

- info@yildizpolietilen.com

- E-Katalog

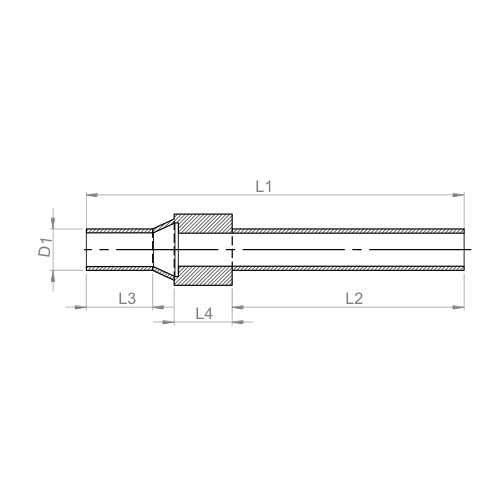

STEEL WELDED TRANSITION

Steel Welded Transition fittings are designed to provide a safe and leak-free transition between polyethylene (PE100) plastic pipes and metal pipes. The steel side of the product is joined to the metal line in the system using appropriate welding methods (e.g. arc welding, TIG, MIG, etc.), while the polyethylene side is integrated into the HDPE pipeline by butt welding or electrofusion (EF) connection technique. In this way, an integrated operation of plastic and metal pipe systems is ensured.

Steel Welded Transition – PE-Metal Pipe Transition Element

Areas of Use:

-

PE-steel pipe transitions in natural gas distribution lines

-

Drinking water and potable water infrastructure systems

-

In systems where different materials are connected in industrial installations

-

Transition connections with different metal pipes such as cast iron, stainless steel or carbon steel

Advantages:

-

Safe and leak-proof connection between plastic and metal lines

-

Easy integration of the plastic side by electrofusion or butt welding

-

High mechanical strength and long service life

-

Corrosion resistant steel structure (galvanized, stainless steel optionally)

-

Full compatibility with pressurized lines such as gas and water

Why Use Steel Welded Transition Fittings?

In infrastructure and superstructure projects where different pipe materials are used, steel transition welded fittings are the ideal solution to provide transition without risking system safety. It protects the integrity of the system by adapting to the technical specifications of both plastic and metal pipes.

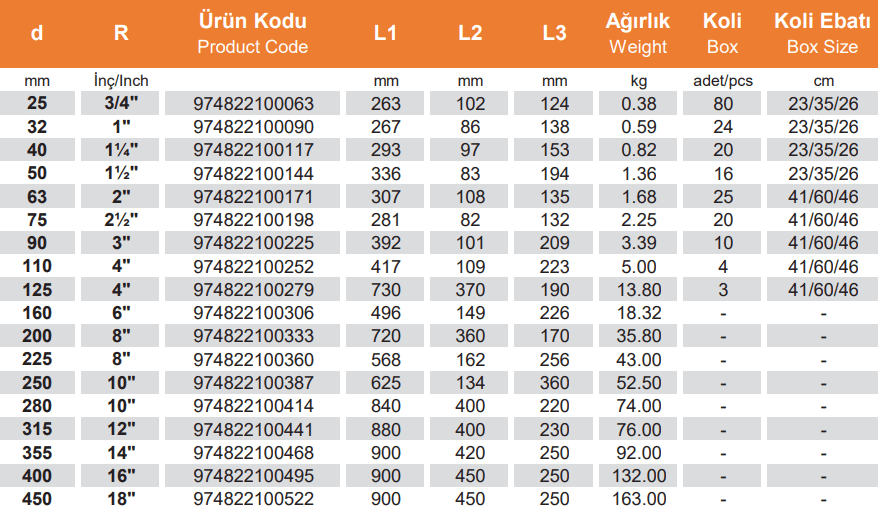

Technical Specifications:

-

PE100 polyethylene and high quality steel material

-

Steel side: weldable plain end

-

PE side Compatible with EF fitting or butt weld

-

Standard dimensions: SDR11 / SDR17

-

Special length, thickness and flange options can be produced upon request